Digital Machining Technology and Know-how for Wood and Composite-panels

stephane

2014-09-02T09:46:03+01:00

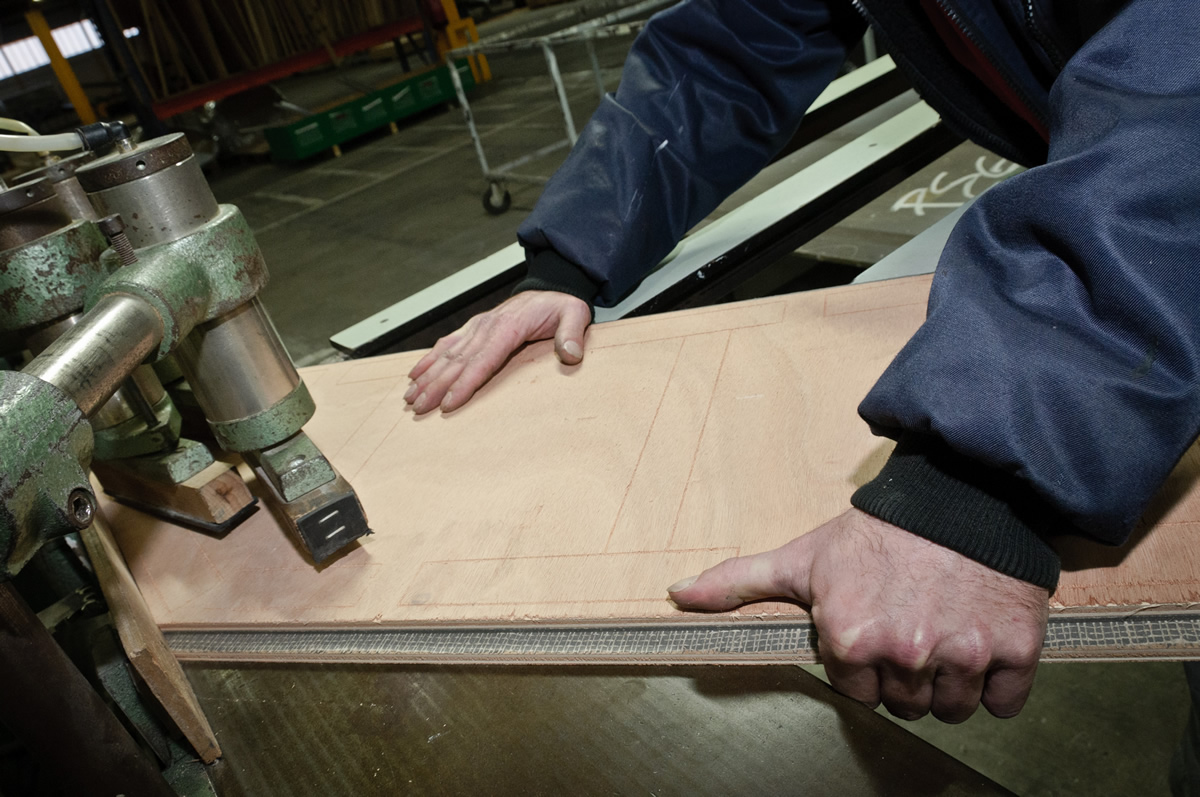

We manufacture various machined parts and panels for the industry. Her is a short presentation of BDR’s know-how.

We want to be a leader. We continually work to offer you solutions and new products that meet your needs.

We are accustomed to working from specifications with

major companies. We can also develop specifications from information received. We carry out a wide variety of subcontracting, thanks to our know-how and technology.

Our CAD/CAM department can help adapt our customers’ requirements and transform them for execution through digital programs on our machines. This work customizes each request by creating a program and optimizing panel machining to reduce costs.

- 3D digital machining up to 2.5x8m

- Sandwich panel lamination

- Work on wood, synthetic, and composite panels.

- Assembly and joining of various metal, electrical, acoustical, and anti-vibration components.

Three axis digital control:

Our tools have the following characteristics:

- Automatic panel loading and unloading

- Automatic tool measurement

- Suction and pressure operation

- Panel automatically felt

- Automated dust ventilation

Moreover, the large size allows machining of large parts, up to 2.5x8m.

Machinery:

- Massicot

- Mortiser

- 4 sided veneering press

- Press

- Jointer

- Punch Plate

- Shaper

- Programmable saw

We can pack our products for any type of transport: pallets, carriage, special packing (vacuum-packed maritime crates)

We can deliver and ship packages all around the world.

We can provide information to each customer on the raw materials used. We can notify our customers of the date, origin, and species of raw materials received and shipped.

We keep digital files for each part. This enables us to replace a product or part of a product at any time.